Airmix External Mix Airless Gelcoater

Simplicity Plus

External mix technology requires no solvent flushing, reducing downtime and material waste.

Low Pollution Environment

Efficient external mix nozzle design with air assist/air containment ensures a thorough catalyst/gelcoat mix. This achieves the lowest PPM levels and significantly lower VOC emissions compared to traditional systems.

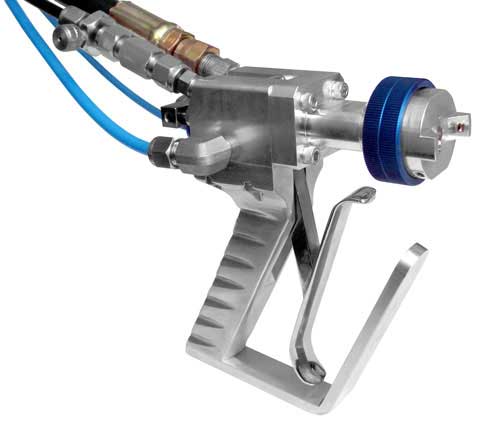

Gun Design

The gun features an all-mechanical design with fewer parts to service or replace. An ergonomic trigger design provides fatigue-free operation for long shifts. The gun weight is an ultra-light 800gms.

Pump Design

A new air valve with quick exhausts on the pump motor provides a fast stroke changeover with minimum moving parts. The auto-adjusting gland in the resin/gelcoat pump extends operating life and lowers maintenance costs.

Catalyst System

The standard system uses a pressure tank feed to an adjustable, highly visible flowmeter (with only one O-ring to service). Alternatively, an accurate catalyst slave pump system is available, adjustable from 1% to 3%.

System Versatility

The Airmix unit is available as a gelcoater, resin saturator, or in multi-pump combinations. It features hardchromed pumps for spraying filled resins. Units come standard on a floor stand with an optional trolley mount.